Eighteen years of experience, and precision that will leave you breathless. Our expert services are also sought by clients from the USA, India, and other parts of the world. But Mecasys is much more than just machines and technology. First and foremost, we are a community.

Your trust. Our mission.

MECASYS is a place of growth and collaboration. Our goal is to build a world-class company in Orava, whose products will even be used by organizations such as ESA and NASA. Our goals may be

large, but we still value people and stick to our core values.

Integrity

and trustworthiness

We're a partner who will not only help you meet your needs but will also turn your visions into reality..

Consistency

We're as precise as possible.

All our products meet high standards of quality.

Expertise

Eighteen years of experience and hundreds of projects. Give us a problem, and we'll give you a solution.

Development

We're constantly progressing, growing, and learning.

Innovation

We develop new products and equipment and implement innovations in manufacturing processes, boosting our reputation as an industry leader.

Reliability

We do what we say we'll do.

This is us

Our journey

2005

Foundation of the company

We founded Mecasys when we were still assistants at university. However, through hard work, reliability, and quality service, we made rapid progress.

2006-2007

Our first large order

We worked on seismic calculations for ZONE 4 for Bel Power Solutions, s.r.o. A year later, we set up a prototype production facility for them.

2009

Milled components

We launched production of milled components for Sony Ericsson.

2012-2013

Expansion and modernisation

We expanded our machine fleet with an EDM cutting machine, a 5AX HERMLE C42 milling machine, and invested in 3D measuring equipment from HEXAGON and MIYANO.

2015

The design department

We opened a design department for the design and supply of jigs to Johnson Controls Automotive.

2016

Addition of technologies

We extended our EDM tool and mould repair capabilities by adding EXERON boring and supplied jigs for GMD Plastic Systems.

2017

Increase in annual capacity

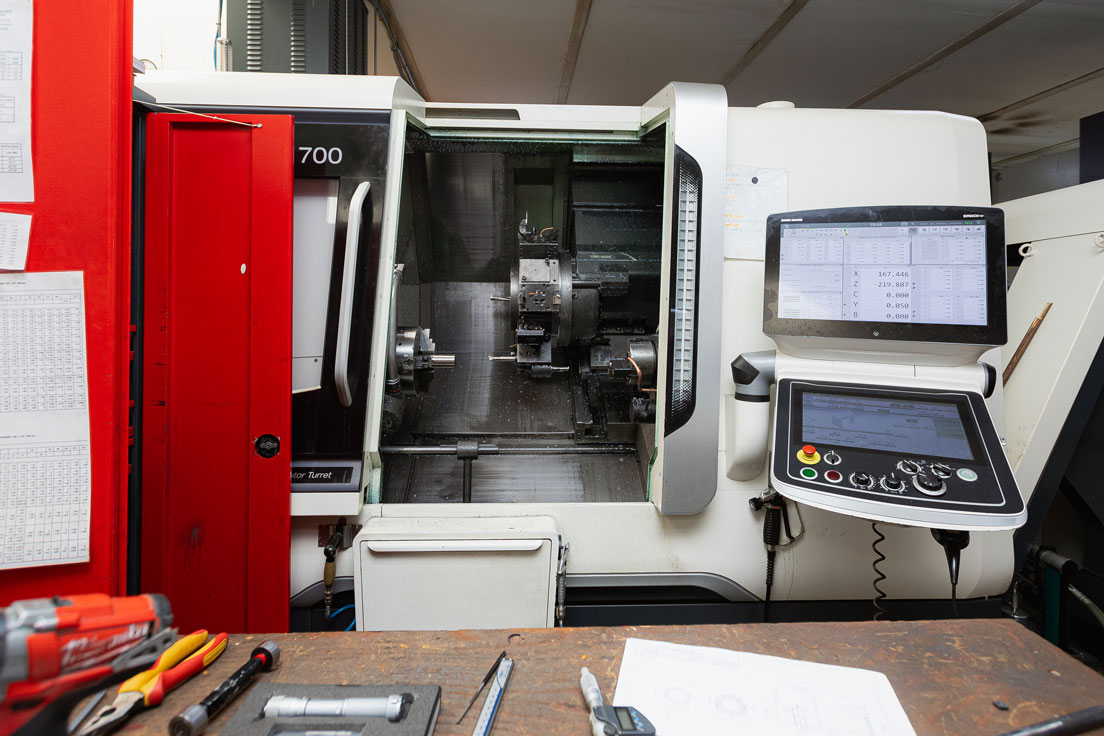

We added DMG CNC lathes to our technology for machining rotary parts and achieved an annual production capacity of 100 measuring jigs.

2018/2019

Other projects

We worked with SCHAEFFLER and SPECAC and worked on another 150 projects for Volvo Car Corporation and Opel.

2020

New CNC machines

We added CNC flat grinding technology, expanded our cooperation with WITZENMANN, and reached the milestone of 320 completed projects.

2021

Even higher precision

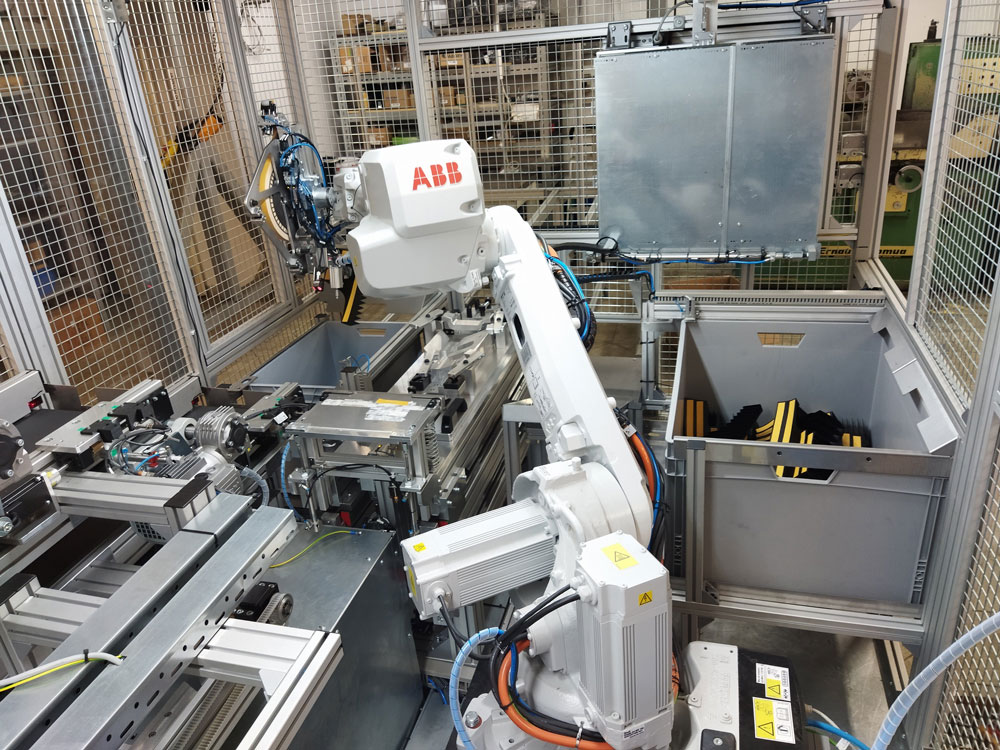

We added CNC cylindrical grinding technologies with an accuracy of +/−0.002 mm. We supplied 120 jigs and stations for Honda, Audi, and Porsche projects. We designed and manufactured an ABB robotic workstation for the assembly and final inspection of a ŠKODA project. We started working with MEOPTA on projects for industry and optical sports equipment.

2022

We're still moving forward

We started work on opening a new production hall. In addition, we supplied an additional 107 jigs and stations for BMW, Audi, Daimler, and ŠKODA projects.

Environmental responsibility

We care about protecting the environment. We strive to minimise our carbon footprint, including through the installation of photovoltaic systems on both of our production halls.

We've saved 39.15 tonnes of coal

We've prevented the emission of 46.47 tonnes of CO 2

Savings equivalent to planting 65 trees